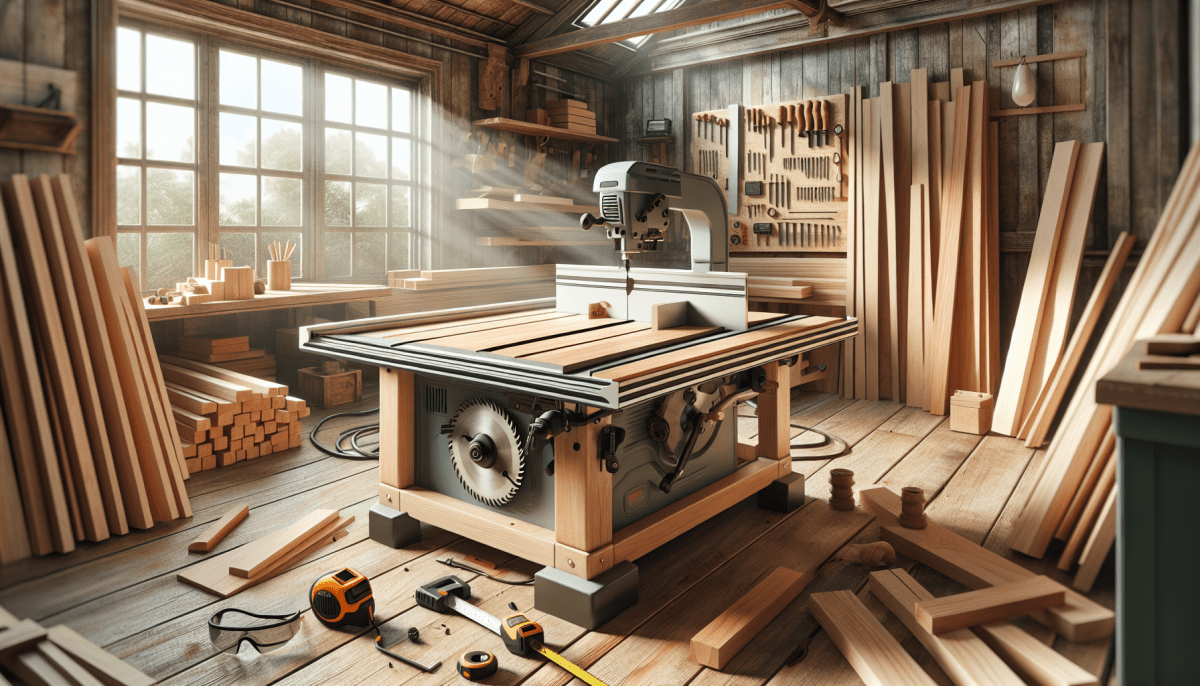

Table saws are one of the most essential tools in woodworking. They are favored by both amateurs and professionals for their precision and versatility. At a basic level, a table saw consists of a circular saw blade mounted on an arbor, which is driven by a motor. The blade protrudes through a flat table surface, allowing for smooth and controlled cuts. Understanding the components of a table saw will make your woodworking projects easier and more efficient.

One of the key features of a table saw is the rip fence. This adjustable guide helps you make straight cuts along the length of your board. Properly aligning the fence is crucial for accuracy, so take the time to set it up correctly before you start cutting. Additionally, the miter gauge is another important component that allows you to make angled cuts. It slides in a track on the table, providing support and guidance as you cut at different angles.

When using a table saw, safety should always be your top priority. Always wear protective eyewear and keep your fingers clear of the blade. Using push sticks or push blocks can help maintain a safe distance from the blade while guiding your workpiece through the cut. Familiarizing yourself with the saw's guards, such as the riving knife and blade guard, will also enhance your safety while working.

In addition to basic cuts, table saws can perform a variety of functions, including crosscuts, bevel cuts, and even dado cuts with the right setup. These capabilities make them incredibly versatile for different types of woodworking projects. As you become more comfortable with your table saw, you'll find that mastering these techniques will expand your woodworking skills and bring your creative ideas to life.

Choosing the Right Table Saw

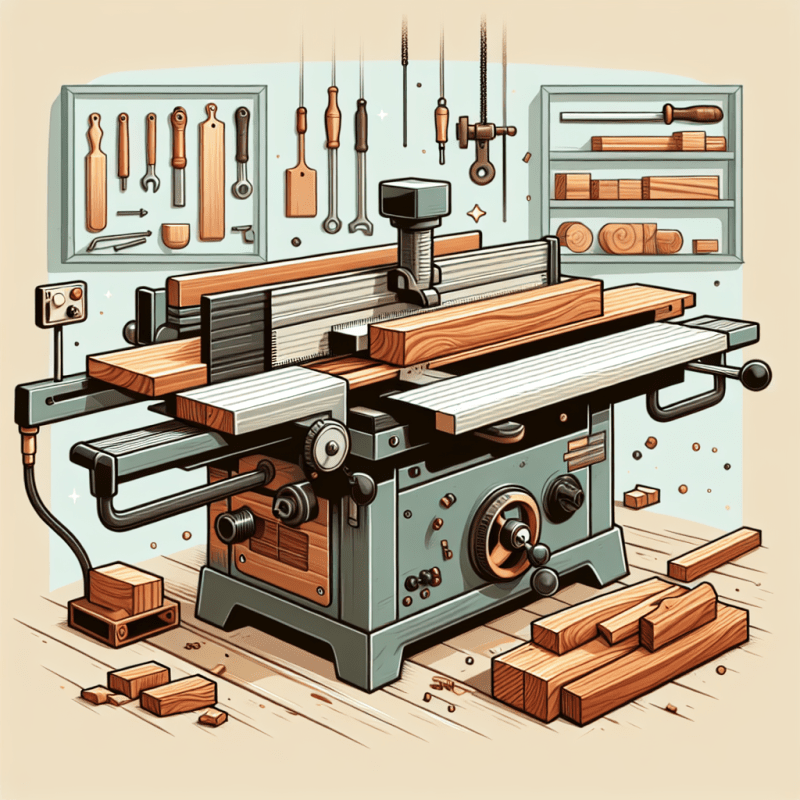

There are three primary types of table saws: contractor, cabinet, and portable. Contractor saws are typically more affordable and easier to transport, making them an excellent choice for beginners or those with limited space. Cabinet saws, on the other hand, are more powerful and durable, designed for professional woodworkers who need precision and efficiency. Finally, portable saws offer the flexibility to work in various locations, perfect for those who need to move their tools frequently.

When choosing a table saw, pay close attention to the motor size, blade type, and safety features. A powerful motor will enable you to cut through thicker materials with ease, while the right blade can enhance the quality of your cuts. Safety features, such as blade guards and riving knives, are crucial for preventing accidents and should not be overlooked.

Another important factor is the size of the table and the extension capabilities. A larger table provides more support for your materials, resulting in straighter cuts. Extensions can also be beneficial for handling larger sheets of plywood or other lengthy materials. Take the time to evaluate your workspace and storage options before making a purchase to ensure you get a table saw that fits both your needs and your environment.

Safety Tips for Table Saw Use

Using a table saw can be one of the most rewarding experiences in woodworking, but safety should always come first. To ensure your projects go smoothly and without injury, follow these essential safety tips while working with a table saw.

First and foremost, always wear appropriate personal protective equipment (PPE). Safety glasses are a must to protect your eyes from flying debris. Additionally, hearing protection can help guard against the loud noise of the saw, and a dust mask can minimize inhalation of sawdust particles. Wearing fitted clothing and avoiding loose sleeves will also reduce the risk of fabric getting caught in the blade.

It's crucial to keep your work area clean and well-lit. Clutter can lead to accidents, so make sure that your workspace is free from unnecessary items. This will allow you to focus on the task at hand and provide ample room for movement. A well-lit area ensures that you can see clearly what you're working on, allowing for more accurate cuts and reducing the likelihood of mistakes.

Before starting your saw, inspect the equipment to ensure everything is in good working order. Check the blade for any signs of damage and confirm that all guards are in place. Always use the proper blade for the material you're cutting, and never adjust the blade height or angle while it’s running. When making cuts, utilize push sticks, feather boards, or other safety devices to keep your hands and fingers away from the blade's path.

Lastly, maintain focus and avoid distractions. It's easy to get sidetracked, but this can lead to costly mistakes or, worse, injury. If you're feeling tired or rushed, it’s best to take a break or finish your work another day. Remember, taking the time to be vigilant pays off in safety.

Essential Table Saw Techniques

When it comes to mastering woodworking with table saws, understanding essential techniques is key to achieving precise and clean cuts. One of the most fundamental skills is knowing how to make accurate measurements and cuts. Always start by measuring your wood carefully and adjusting the blade height and angle as needed. Using a reliable measuring tape and square will ensure your cuts are true, and repeating measurements can help prevent costly mistakes.

Another crucial technique is using the fence properly. The fence is designed to provide a straight edge for your materials. Make sure it is parallel to the blade, as misalignment can lead to inaccuracies and potential safety hazards. When working with larger sheets of plywood or boards, consider using additional supports to keep your workpiece stable and secure during the cut.

Feeding the wood through the saw safely and efficiently is also vital. Always push the wood through with steady pressure, and never place your hands close to the blade. A push stick is an excellent tool for ensuring your fingers are at a safe distance while still maintaining control over your workpiece. Practice maintaining a consistent feed rate to achieve smooth cuts without the risk of kickback.

Lastly, mastering the art of using jigs can elevate your woodworking projects significantly. Jigs can assist with repetitive cuts, angled cuts, or even creating intricate joinery. Investing time in building a few jigs for specific tasks will enhance accuracy and save you time in the long run. Explore common jigs like crosscut sleds, taper jigs, and dado jigs to expand your cutting capabilities and improve your overall woodworking skills.